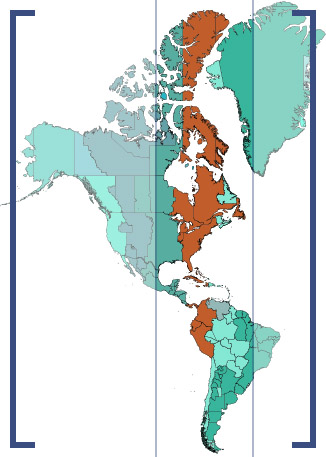

Nearshore Manufacturing Services

We offer North American companies' significant advantages in electronics manufacturing. We leverage free trade agreements for cost savings and time zone alignment for real-time collaboration. Our nearshore solutions in Mexico and Colombia, backed by local, US-based technology and business support, enabling faster time-to-market, quality, scalable production, and a competitive edge for your business.

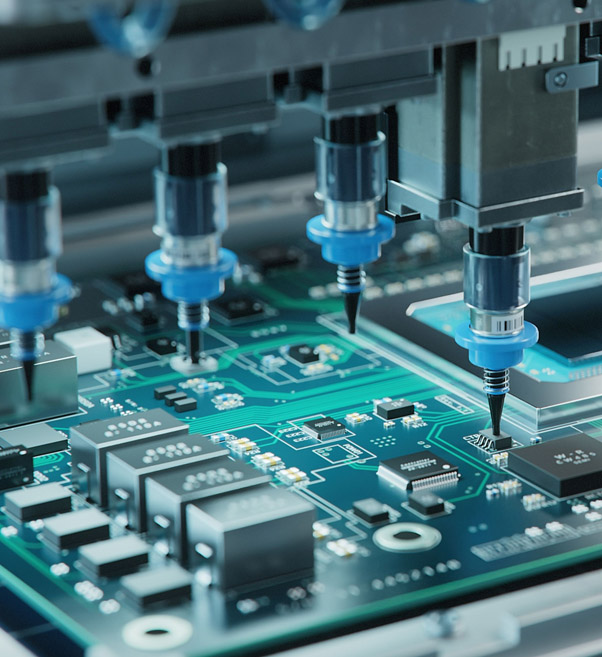

PCB Manufacturing

- 2 Weeks prototype production; 50K Units/month production capacity

- Automated Surface Mount Technology (SMT) assembly

- Electrical testing of individual components on assembled PCBs (ICT)

- Conformal coating application

Cable Harness

- 2 Weeks prototype production; 50K Units/month production capacity

- Automated Surface Mount Technology (SMT) assembly

- Electrical testing of individual components on assembled PCBs (ICT)

- Conformal coating application

Sub-Assembly

- 2 Weeks prototype production; 50K Units/month production capacity

- Specialized production of modular components for larger systems or products

- Precision assembly of electronic, or electromechanical sub-assemblies

- Comprehensive testing protocols to ensure functionality and reliability

- Integration of quality control measures throughout the manufacturing process

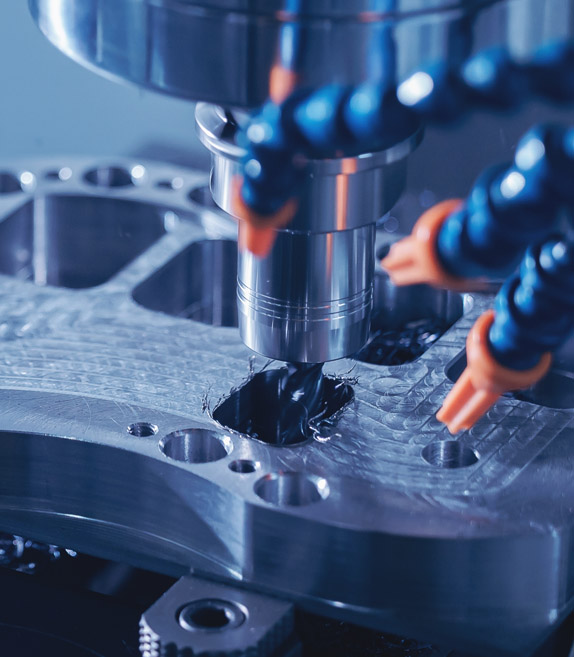

Metalworks

- Precision Machining: Up to 7 axis CNC Turning; Up to 5 axis CNC Milling; Swiss CNC Turning

- Forged Parts: Hot/cold open/closed die seamless forging

- Casting: Sand, gravity die, pressure die, investment, plaster, centrifugal, lost-foam/3D printout casting, vacuum casting

- CNC fabrication, welding and stamping

Our Process

Assessment & Planning

- Evaluate client needs and project requirements

- Analyze potential cost savings and benefits

- Develop a customized outsourcing strategy

Onboarding

- Establish first article agreement including quality standards, specifications

- Develop and test prototypes

- Iterate, collaborate to facilitate design for manufacturability (DFM)

Production

- Design transfer of necessary technology and knowledge

- Begin production with close monitoring and quality control

- Optimize processes for efficiency and cost-effectiveness

Improvement & support

- Provide ongoing US-based technical and business support

- Regularly assess performance and implement improvements

- Scale production as needed